Currently, thousands of people are waiting on the transplant list for organs like kidneys, heart, and liver. Unfortunately, there are not nearly enough donor organs available to fill that demand. You also cannot donate an organ such as a heart while the patient is alive. What if instead of waiting, we could create a brand new customized organ? That is the idea behind bioprinting.

This technology is still in development but there are already printers out there capable of performing the impossible a few years ago. The consensus is that rather than printing cells layer by layer as in regular 3D printing, 3D printing of organs should be done by printing scaffolds on which cells can grow and develop into a full size organ.

As you can imagine with such an undertaking on the cutting edge combining 3d printing technology, medicine and biology, this is not something that comes at a low price. Let’s discuss the costs of printing organs.

The cost of 3D printing organs is changing as technology evolves. Living tissue has been successfully printed with a $1000 3D printer while more specialized bioprinters cost upwards of $100,000. Other costs involved include bioinks which start at hundreds of dollars, associated research and the cost of highly skilled operators for 10 weeks or more per organ. It is not uncommon for the initial cost of bringing a bioprinting technology onto the market to be in the tens of millions of dollars.

According to the National Foundation for Transplants, a standard kidney transplant can cost up to 300,000 dollars. But compared to that if a kidney is printed through a printer and if they are suitable for use in the human body then the cost will be much less. Companies such as Bioscience, Volumetric, FluidForm, Printivo are working on 3D-printed organ services.

It is not all easy going, and companies pioneering in this space have to face huge start up costs in the millions of dollars to bring their technology to market. Operating losses can be very high. Funds are usually obtained from grants and private investors. Another limitation is getting through all the usual red tape and testing tissue first in animals and finally in humans years later if approved.

What are 3D printed organs made of?

The world of 3-dimensional bioprinting or 3D organ printing is very complex. Polymers such as Hydroxyapatite, Titanium, Chitosan, and collagen are used that need to be biocompatible and capable of having cells attach to their scaffold and grow into an organ.

BioInk:

A bioink, which can be thought of as printer ink for bioprinting, is a a hydrogel material combined with cells. Using bio-inks provides high reproducibility and precise control over the fabricated constructs in an automated manner.

Bioinks are able to support the growth of various cell types. They come as a ready-to-use gel for printing 3D tissue models. They are versatile and biodegradable. BioInk is usable for long-term tissue cultivation such as many weeks.

OsteoInk:

Calcium Phosphate material for 3D tissue printing is called as OsteoInk. OsteoInk is a ready-to-use calcium phosphate paste for structural engineering. OsteoInk is a highly osteoconductive biomaterial close to the chemical composition of human bone. It is used to make various types of hard tissues in the human body such as bones, cartilage, or structural scaffolds.

OsteoInk can be combined with BioInk to create complex 3D tissue mimetic models. It controls the uniqueness of the bioprinter by enabling freeform fabrication of the tissue model, creating tissue layers, pore formation, and biological structure. BioInk is often used with OsteoInk to reduce opacity.

In addition to BioInk and OsteoInk, special ingredients like Agarose, Collagen, Alginate, Polyethylene, Glycol, and Gelatin are used for 3D Bio-printing.

Why is printing organs difficult?

Transplantation of 3d printed organs could be a revolution in medical science. However, many issues stand in the way. Researchers are working hard to create a directly replaceable organ. Many companies are working day after day to make it possible. They are constantly facing many problems while doing this research. As with organ transplants in the human body and rejection, the recipient often faces some problems. What are those unresolved obstacles? Let’s see what problems scientists have to go through in this work.

Limited options for Biomaterials:

Collecting the biomaterials that are used to support and structure the cells that make up a functional printed organ is a difficult task for scientists.

As mentioned earlier, Synthetic polymers and Hydrogel are used for 3D organ printing. Synthetic polymers are mechanically strong and suitable for printing but may lack cell adhesive properties to support cell growth. Meanwhile, natural polymers are not as strong as synthetic polymer polymers but are much more suitable for cell attachment, expansion, and differentiation.

Scientists have recently printed a heart using a 3D bioprinter. The main ingredient in the artificial heart was Alginate, and it was taken from a type of algae that lives in the deep sea. They chose nano cellulose and alginate because these plant-based materials naturally support the power of plant micro-architectures to aid cell growth.

Maintaining the shape of the soft material:

The key to printing three-dimensional functional organs is to maintain the structural integrity of the organ. The shape of the artificial organ often depends on the viscosity of the BioInk used in the printer.

Biodegradable scaffolds made from biomaterials have often been used to maintain the shape of bioprinted tissues and seed cells, but scaffolding defects include stimulating immune responses, as well as cell detachment from potential toxicity and decay by-products.

Bioprinters:

Printers have become one of the major problems for bio-printing. Some minor flaws in the use of printed organs in the human body can become a major problem. Often, the entire printing is ruined due to a printer hardware error. An error in organ printing occurs when the printer is interrupted for some other reason.

Below is a good TED Talk video on how bioprinting works:

Which 3D printers are used for organ printing?

Bioprinting can be done with inkjet based and extrusion based methods, as well as SLA, FDM and SLS.

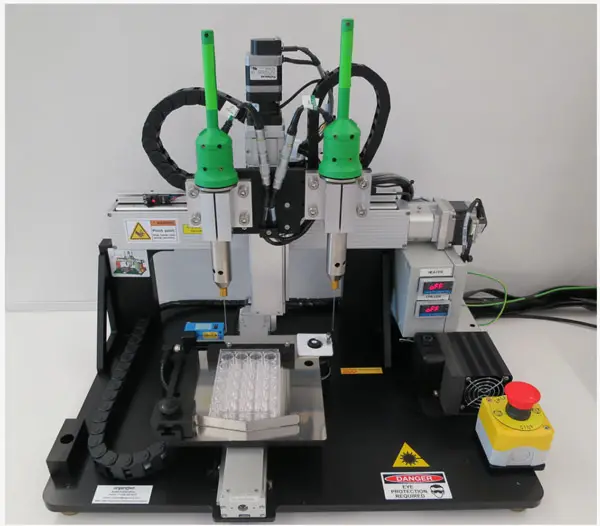

BioInk is used as the main printing material for 3D organ printers. A bioprinter uses polymeric materials and cellular hydrogels, such as syringes or professional extrusion paste. But plastics are used as the printing material of ordinary printers. So a bioprinter should never be compared to a normal printer. Currently, many companies are working on making and improving bioprinters.

Bioprinters are available at different price points and qualities on the market. The bioprinter made by ‘EnvisionTEC’ is the latest type of a bioprinter. This printer converts computer-aided tissue engineering 3D models and patient CT data into a physical 3D scaffold. This printer is called ‘ 3D Bioplotter’.

The ‘NovoGen MMX’ made by Organovo is a much better quality bioprinter. They have created this for their own use only. This bioprinter is only used to make beneficial tissues. Organovo does not sell its ‘NovoGen MMX’ technology.

“Organovo BioPrinter” by NIH-NCATS is marked with CC PDM 1.0

RegenHU’s ‘3DDiscovery’ bioprinter is one of the most expensive printers. The printer uses two printing methods and utilizes various hydrogels, bioactives, cells, and extracellular matrix materials. It is capable of enabling dynamic protein networks as well as cell/cell interactions.

These are very advanced printers. Also, there are some less expensive printers available in the market. Typically, these start at 10,000 dollars. But, buying a good quality printer can cost up to 200,000 dollars. One of the less expensive printers, ‘Alpha & Omega’ is a 3D printer made by ‘3Dynamic Systems’. It works on syringe-based extrusion technology.

Developers are still working on some sophisticated and open-source models of 3D printers, which have not yet hit the market. However, the hope is that when they come on the market, 3D bioprinters can be used at a very low cost and open to all.

Here is a price guide for some of the more expensive bioprinters.

Other uses for 3D printing in medicine

3D printing technology is very important in the field of medical science. 3D-printed organs have been used in many large and complex surgeries as reference. From the human brain to the smallest bones of the body, 3D printing has been used. 3D printed anatomical models are important for medical improvement. Surgeons can take less time in surgery by planning and practicing an operation on a custom 3d printed copy of a patient’s organ.

I hope that this article has given you some idea about what is involved in 3D printing of organs, including the costs. Click the following link to learn how to 3D print wax.